Air compressors are a necessary part in numerous industries, giving the essential compressed air for pneumatic tools, production lines, and other applications. One of the essential facets of running air compressors successfully is moisture prevention and appropriate maintenance. No matter of the kind of compressor-- be it a two-stage oil-injected rotary screw air compressor or an oil-free screw air compressor-- moisture can create significant problems otherwise handled correctly. Moisture inside the air system can cause corrosion, mold and mildew, and wear and tear of tools in time, impacting not only the compressor itself but additionally the devices and machinery it powers.

To alleviate moisture troubles in air compressors, it is essential to initially comprehend the mechanics entailed in moisture generation. When air is pressed, its temperature level increases, and upon growth, it condenses and cools down, developing moisture. This sensation occurs in all sorts of screw air compressors and piston air compressors, and it can be exacerbated by high moisture degrees in the surrounding atmosphere. As a result, moisture usually ends up being a substantial concern in operations where air compression is applied. Carrying out moisture control strategies, such as the usage of refrigerated air clothes dryers and desiccant air clothes dryers, can effectively remove moisture from the compressed air system. Refrigerated air clothes dryers cool the compressed air, permitting moisture to condense and be eliminated, whereas desiccant air clothes dryers make use of moisture-absorbing products to guarantee that the air provided is as dry as feasible.

A two-stage oil-injected rotary screw air compressor is created to operate at higher efficiency degrees and decreased moisture generation compared to a single-stage layout. Regardless of its performance, all oil-injected screw compressors are susceptible to moisture entry if the consumption air is not sufficiently filtered. Furthermore, knowing whether to make use of an oil-injected screw air compressor or an oil-free screw air compressor is vital depending on the application.

In industrial setups, larger air compressors, such as those from China air compressor makers, are frequently coupled with additional parts to enhance their functional efficiency and long life. These elements could include additional moisture separators, which are valuable in recording and eliminating moisture before the air is supplied to pneumatic devices. It's also typical to see nitrogen generators or oxygen generators linked to air compressor systems, especially in specialized applications where certain gas make-ups are needed. Recognizing how these accessories function in conjunction with the compressor is basic for preserving optimum performance and preventing moisture build-up.

For operators of portable air compressors, moisture control becomes even much more crucial, as these machines operate in numerous settings, commonly under less-than-ideal conditions. Regular inspections for leakages or obstructions in the system will not only protect against moisture access however also advertise effective air shipment and reduce power usage.

When talking about vacuum pumps, such as oil-injected air pump, it's vital to note that they also call for moisture administration approaches. Oil-free vacuum pumps offer a choice for applications where moisture may be detrimental. Comparable to their screw compressor counterparts, maintaining a vacuum pump without moisture extends its life-span and guarantees preferred operating conditions. For rotary vane air pump, which are typically made use of in industrial procedures, setting up ideal filtering systems aids guard versus moisture damages, therefore prolonging the functional life of the pump.

Efficient air compressor maintenance need to consist of routine checks of the compressor's oil top quality in oil-injected machines. Moisture can contaminate compressor oil, minimizing its efficiency and leading to equipment failure.

Comprehending the ambient conditions where the compressor runs can assist establish a preventative maintenance routine customized to certain ecological difficulties. In areas with high humidity, there could be a demand for extra desiccant systems or upgrades to existing dryers to deal with enhanced moisture degrees.

Affordable sectors require to manage air compressor systems effectively to prevent sustaining high operating expenses. This is where energy-efficient air compressor technologies enter into play. Compressors that integrate innovative technology and maintain optimal moisture levels can substantially lower power intake contrasted to older or inadequately kept models. Furthermore, lots of modern-day systems provide real-time efficiency surveillance, making it possible for fast identification of moisture problems before they escalate right into expensive fixings. Using wise innovation can assist operators maintain effectiveness and reduce the risks associated with moisture.

The understanding of moisture monitoring does not only finish with the compressors themselves, yet additionally consists of the devices and devices that the pressed air is utilized to power. Pneumatically-driven devices, as an example, can be badly affected by the visibility of moisture. Damp conditions can bring about cold of air devices in chillier atmospheres, causing operational inefficiencies and raised maintenance costs. Investing in top quality moisture separators at points of use can become a critical component of moisture administration within pressed air systems.

Finally, moisture prevention and maintenance are important for the optimum procedure of air compressors, whether they are two-stage oil-injected rotary screw here air compressors or oil-free options. Recognizing the certain needs of the compressor type being utilized, executing moisture control strategies like refrigerated and desiccant dryers, and adhering to a strenuous maintenance routine can prevent moisture-related concerns effectively. This incorporated method not just enables improved long life of the compressors and associated devices yet also brings about boosted total effectiveness, reduced functional costs, and an extra reputable supply of pressed air. By placing get more info emphasis on these aspects, drivers can make sure that their air compressors and pneumatic tools continue to be in prime condition, supporting their organization objectives and productivity for the future.

Luke Perry Then & Now!

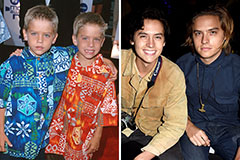

Luke Perry Then & Now! Dylan and Cole Sprouse Then & Now!

Dylan and Cole Sprouse Then & Now! Barbi Benton Then & Now!

Barbi Benton Then & Now! Raquel Welch Then & Now!

Raquel Welch Then & Now! Katey Sagal Then & Now!

Katey Sagal Then & Now!